Employ controlled high-force linear actuation with high-expansion anchoring capability.

全国最大的快3平台-全国快3信誉最好的老平台

Published: 06/30/2020

Published: 06/30/2020

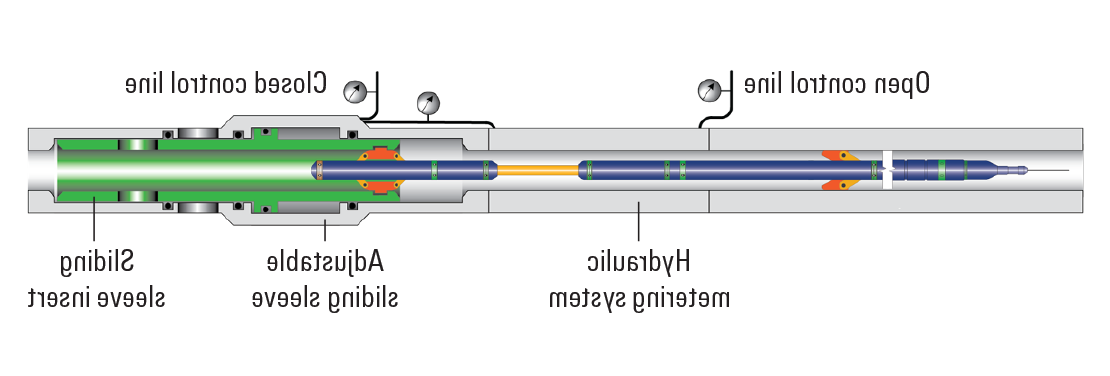

In 2019, an operator of a multizone, smart development well in the Gulf of Mexico was unable to establish production after running the initial completion due to issues with opening two adjustable sliding sleeves. The operator designed the smart completions to minimize intervention because the water depth where the field was located made workover costs prohibitive. Moreover, the sliding sleeves were designed to be controlled at the surface by hydraulics from a nearby production platform, enabling downhole choking capability of the comingled production zones. The sliding sleeve hydraulic metering system had minimal instrumentation measurements, limited to pumped hydraulic volume and downhole pressure to verify if the sliding sleeves were functioning correctly.

When the well was completed, both sliding sleeves appeared to be stuck in their closed position, preventing well production. The operator did not know the root cause or the extent of the downhole failure but suspected that the sliding sleeves' immobility could be due to the hydraulic metering system installed downhole with the completion. This situation created an opportunity to deploy and utilize the fully instrumented ReSOLVE iX service to mechanically shift the two sliding sleeves and use comprehensive measurements to define an optimal remediation plan if the sleeves were unable to remain open.

Due to the minimum restriction of a 2.56-in OD, Schlumberger recommended intervention with 2.125-in ReSOLVE iX service configured with the anchor-linear actuator and smart shifting tool (SST) to latch and shift the sliding sleeves open. The tools' instrumentation enables control and monitoring of anchoring, linear actuator extension and retraction movement to millimeter resolution, and shifting progress.

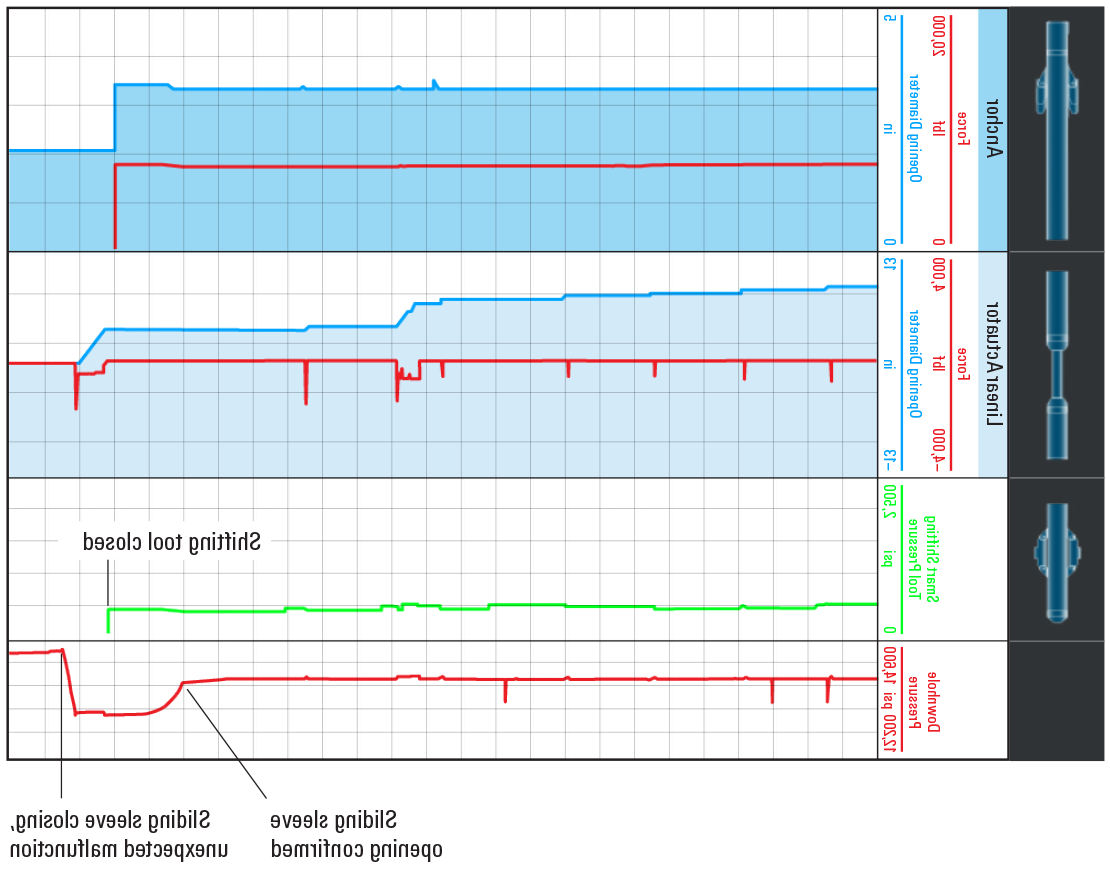

First, the SST was run in hole and positioned below the first sliding sleeve. The linear actuator module was then extended, and the shifting keys were opened in seek mode to navigate through the internal diameter changes and locate the shifting profile. Once the shifting profile was located, the shifting key radial force was increased to secure the position, and the anchors opened to start shifting.

The operator used the enhanced control of the SST and elected for slow actuation of the sliding sleeve. From the ReSOLVE iX service downhole borehole pressure reading, the sleeve was confirmed fully opened. The shifting keys were then completely disengaged from the sleeve as confirmed by the shifting pressure. An unexpected increase of downhole borehole pressure was observed from the tool, indicating that the sliding sleeve had closed itself. Because the sleeve would not remain open, the operator used ReSOLVE iX service for further investigation by measuring the movement of the sliding sleeve when it is operated by hydraulic pressure from the surface control unit. The shifting profile was consequently latched again. Without pulling out of hole, ReSOLVE iX service was switched to diagnostic mode, enabling the linear actuator, without generating any force, to read the sliding sleeve displacement when surface actuated.

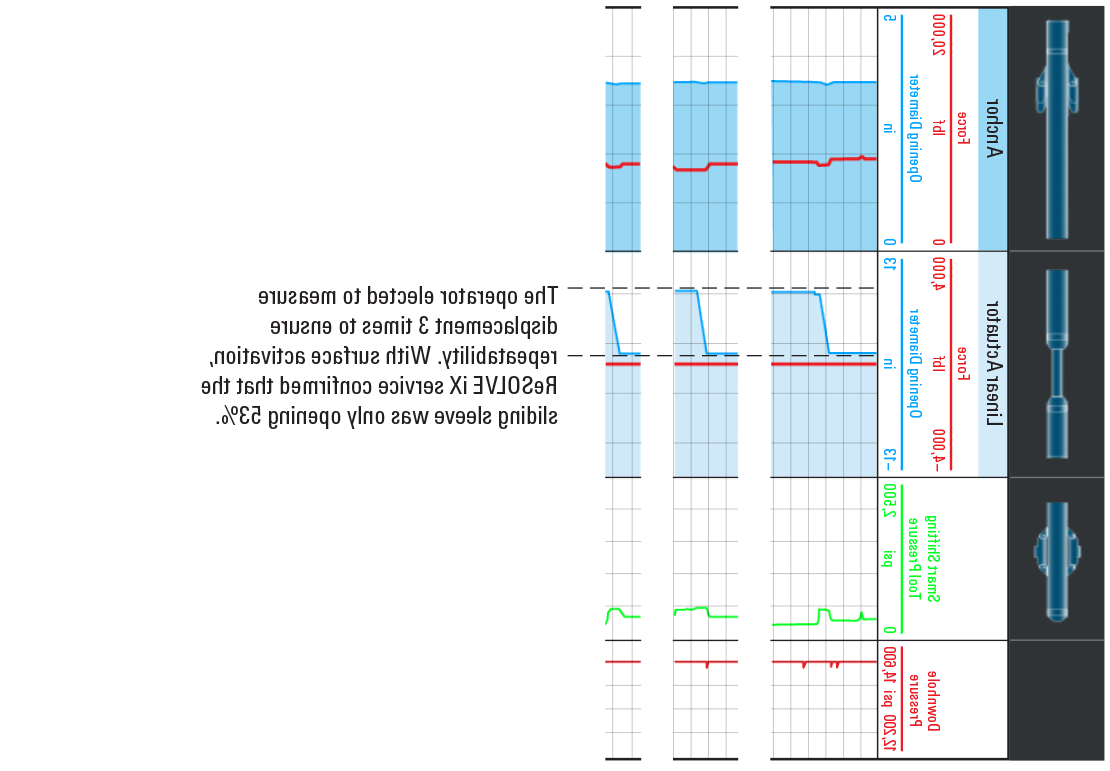

The operator started operating the sleeve from the hydraulic surface control system to move the sleeve upward in the open position. The linear actuator module reading showed a total movement of 8.5 in, 53% of the total 17-in displacement, to a fully opened position that was repeatedly measured.

The second sliding sleeve was also intervened and diagnosed in a similar manner using ReSOLVE iX service. The second sleeve was also found to be faulty and did not fully open.

With downhole measurements from ReSOLVE iX service, the operator was able to understand both sliding sleeves’ behavior and made informed decisions in real time. The operator elected to cut both sliding sleeves, which reinstated the sliding sleeve operation for future intervention and put two nonproducing zones back in production. This avoided a USD 60 million completion workover operation.

For more information, read SPE-199808.

The anchor-linear actuator and smart shifting tools of the ReSOLVE iX extreme performance instrumented wireline intervention service were successfully deployed at 27,700 ft to shift two sliding sleeves, measuring the movement of the sliding sleeves when operated by hydraulic pressure from the surface control unit without pulling out of hole.