Anchor–Linear Actuator Tool

ReSOLVE Family instrumented wireline intervention services

Employ controlled high-force linear actuation with high-expansion anchoring capability.

Published: 10/12/2020

Published: 10/12/2020

An operator of a well in the inland waters of Louisiana was unable to break a ceramic disc to put a well in production because debris had settled on top of it. The debris was too compacted to be removed with slickline bailers. An efficient, effective method to remedy the compacted debris was needed.

Unlike conventional intervention tools, ReSOLVE iX instrumented wireline intervention service enables comprehensive real-time measurements and feedback from downhole conditions for live control of the intervention and informed decision making. ReSOLVE iX service is modular and can be customized for maximum performance during cleanout and shifting operations.

To achieve milling in difficult applications, the downhole MillOptimizer autonomous milling system orchestrates the combined action of the TuffTRAC iX extreme-performance wireline tractor and ReSOLVE iX service milling tool. This enables operators to react fast and minimize surface latency and bit stalling to ensure an efficient and effective milling operation.

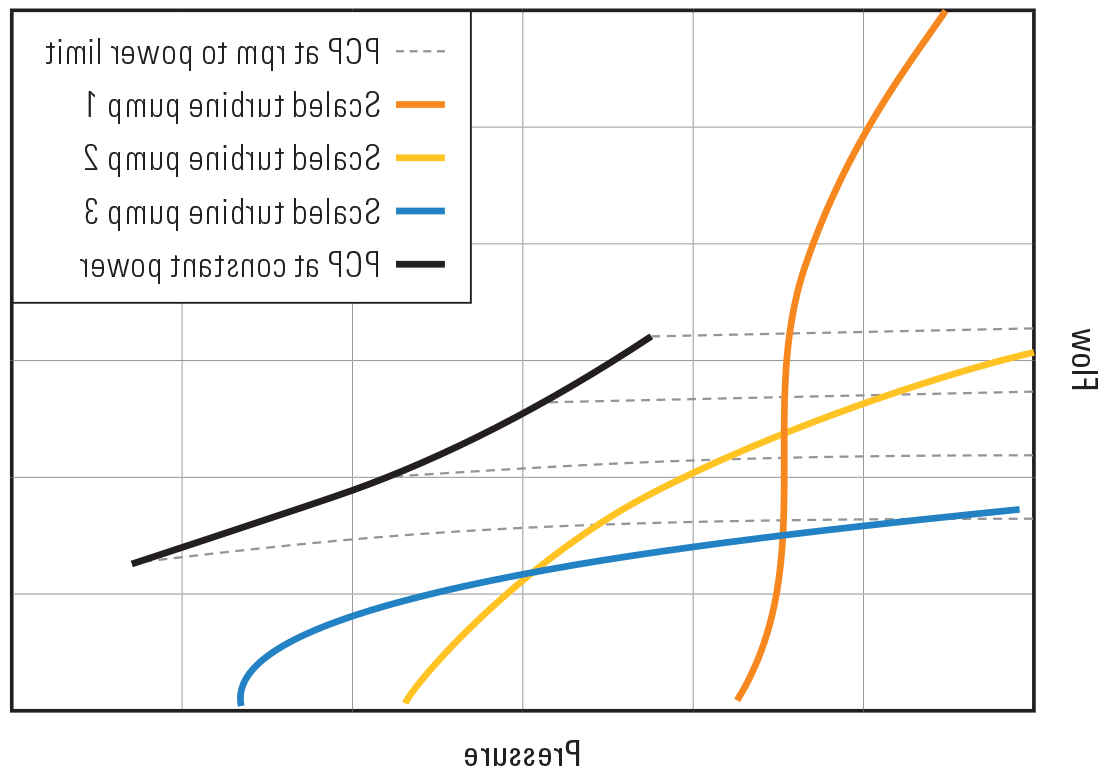

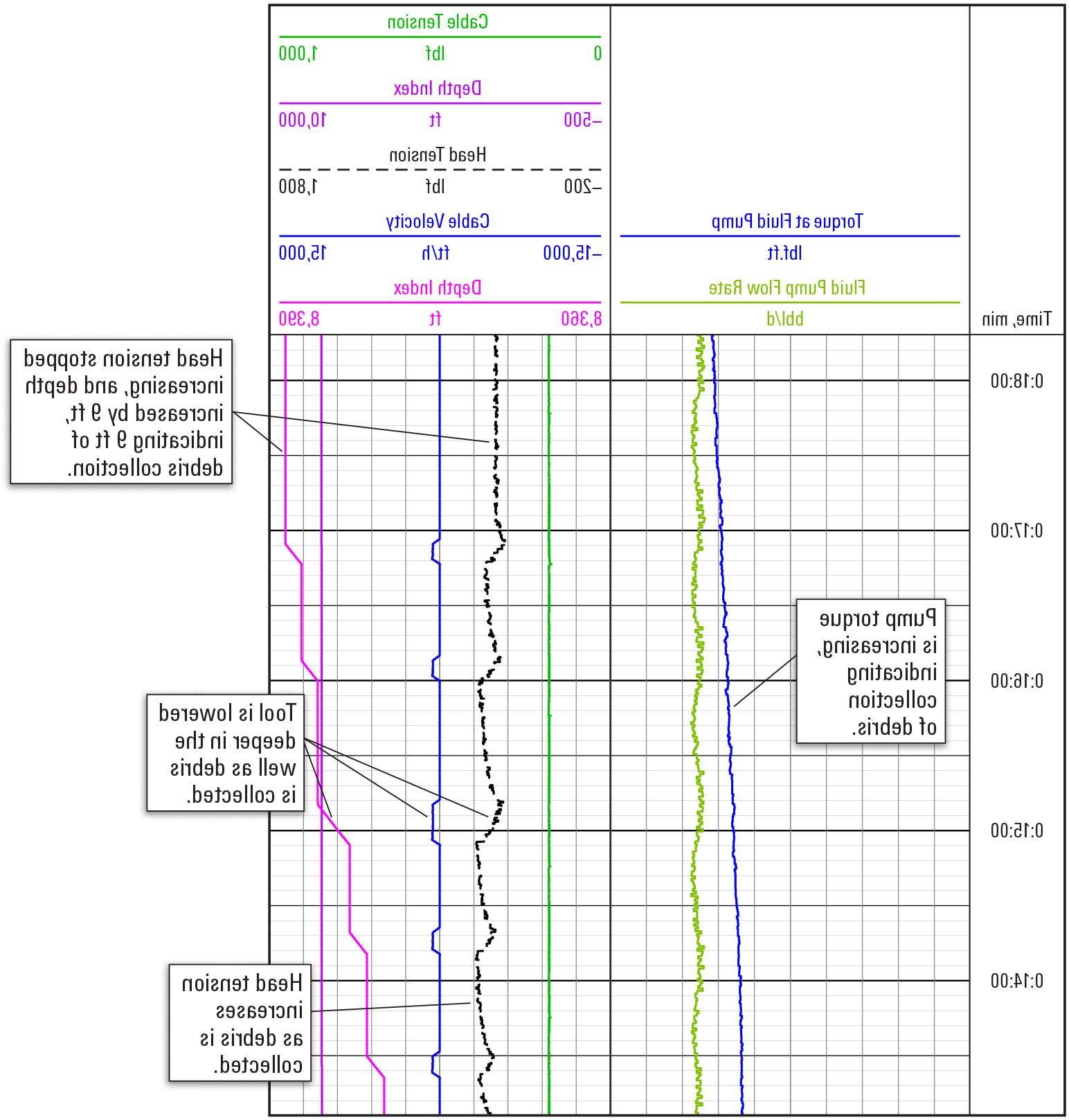

A depth determination run performed to confirm the slickline depths found approximately 15 ft of fill on top of the disc. The ReSOLVE iX service active debris removal tool is the industry’s most powerful cleaning tool using a unique progressive cavity pump (PCP) to generate localized circulation of the wellbore fluid while enabling real-time monitoring of the tool’s performance status and dynamic control of the tool’s operation. Compared with a turbine pump, the PCP has more powerful suction and minimizes the number of cleanout runs required. The second cleanout run reached within 2 ft of the ceramic disc.

To equalize the casing annulus pressure and reduce equalization risk during disk breakage, the anchor, linear actuator, and smart shifting tool of the ReSOLVE iX service were run to shift open a sliding sleeve which was located above the ceramic disc, dropping the fluid level and hydrostatic pressure in the tubing. The instrumentation of ReSOLVE iX service provided accurate real-time measurement of the shifting force and displacement to monitor, control, and confirm shifting progress.

The milling tool was then deployed in seamless integration with the TuffTRAC iX tractor to mill the remaining compacted debris, providing access to the ceramic disc. The exposed disc was easily broken in the subsequent run to put the well in production. The operator saved costs and the 2 weeks required to mobilize a workover rig and perform a workover operation by using ReSOLVE iX instrumented service operation in combination with the TuffTRAC iX tractor, only requiring wireline footprint.

For more information, read SPE-194279.

To start production, a disc buried in debris fill that could not be bailed on slickline was accessed by deploying the ReSOLVE iX extreme-performance instrumented wireline intervention service's active debris removal, smart shifting, and milling tools—saving time, opex, and operational footprint: The operator was able to start production 2 weeks earlier with reduced energy consumption and carbon emission compared with using a workover rig.